Today’s topic is “Applications of Process Performance and Product Quality Monitoring System”

- Pharmaceutical companies should plan and execute a system for the monitoring of process performance and product quality to ensure a state of control is maintained.

- An effective monitoring system provides assurance of the continued capability of processes and controls to produce a product of desired quality and to identify areas for continual improvement.

- The process performance and product quality monitoring system should:

- Use quality risk management to establish the control strategy. This can include parameters and attributes related to drug substance and drug product materials and components, facility and equipment operating conditions, in-process controls, finished product specifications, and the associated methods and frequency of monitoring and control. The control strategy should facilitate timely feedback/feedforward and appropriate corrective action and preventive action.

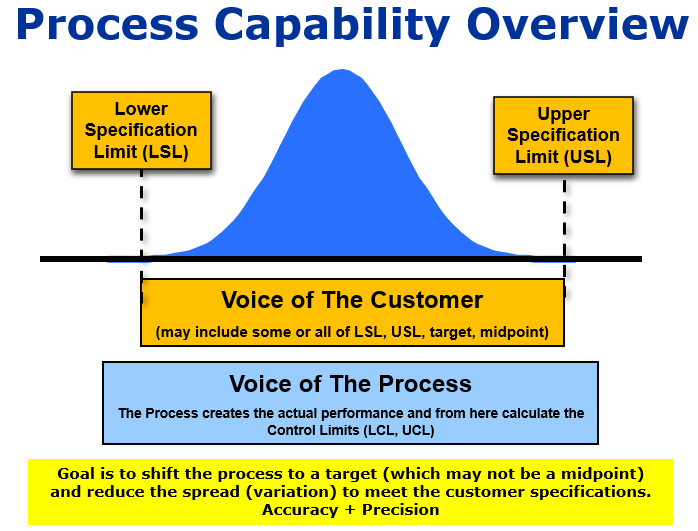

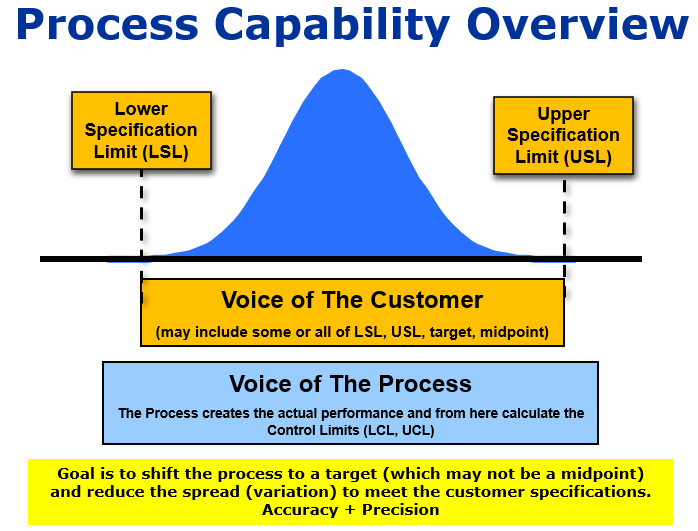

- Provide the tools for measurement and analysis of parameters and attributes identified in the control strategy (e.g., data management and statistical tools).

- Analyse parameters and attributes identified in the control strategy to verify continued operation within a state of control.

- Identify sources of variation affecting process performance and product quality for potential continual improvement activities to reduce or control variation.

- Include feedback on product quality from both internal and external sources (e.g., complaints, product rejections, non-conformances, recalls, deviations, audits and regulatory inspections, and findings).

- Provide knowledge to enhance process understanding, enrich the design space (where established), and enable innovative approaches to process validation

Thank you for reading the FWQRC blogs